Calibrating industrial temperature sensors

Temperature calibration

Industrial temperature measurement and control are two of the most dynamic subsets of the process control industry. Sensors are manufactured in every size, shape, length, and accuracy imaginable to fulfill a specific temperature application. In many cases, probes and probe assemblies are chosen not based on the application’s success, but on other factors such as price, expediency, or availability.

The calibration of an industrial temperature sensor should be well thought out in the early design stage of the process. Doing this early on ensures a better match of the sensor to the application, which means better overall accuracy and reduced intrinsic uncertainty.

To correctly calibrate a temperature sensor in use or before its use, four critical factors must be considered:

Understanding the dynamics of the entire process

Choosing the sensor that best fits the application

Calibrating the system to best emulate the process

Managing the re-calibration of the sensor to assure quality assurance

Industrial process temperature measurements are more critical than ever. Attempts to improve the quality or efficiency of industrial processes has led to a rapid increase in the number of temperature sensors installed in these systems as well as increased requirements for measurement accuracy. There are many sources of measurement error present in these systems. This discussion will focus on the sensors themselves. Temperature sensors are generally designed for a particular measurement application, not the ease with which they can be calibrated or supported. The resulting variety of shapes, sizes, and types may limit the calibration accuracy and often compounds an already difficult support situation. In some cases, the sensors chosen for an application may not be the best choice for the measurement attempted in that application, creating additional measurement error.

To reduce the measurement error to acceptable levels, all aspects of the process measurement and its traceability must be considered. This includes the suitability of the sensor to perform the measurement of interest (its match to the process), as well as the calibration of the sensor and its stability in the field. Best results are obtained when this is accomplished early in the design of the process or prior to the actual implementation of the measurement scheme. It is often much more difficult and costly to salvage an inadequate measurement system than to install or implement a satisfactory measurement system in the first place.

To that end, there are four critical factors to consider which directly influence the capability of the measurement system.

Understanding the dynamics of the entire process being measured

Selecting the sensor that adequately fits the application

Calibrating the sensor in a way which best emulates the process

Managing the calibration of the sensor to assure quality assurance

Process evaluation

The first step in designing a temperature monitoring or control application is a thorough examination of the process itself regarding the dynamic thermal properties of the process. Some of the questions which should be answered are listed below.

What is the origin of the heat?

What is the mode of transmission?

Is the process static or dynamic?

Why is it being monitored?

What accuracy is required?

Will the sensor be subjected to harsh environment?

Are there contaminants or chemicals present?

What are the implications of measurement errors?

Let’s assume that you need to monitor a typical autoclave independent of the unit’s internal control. You will want to understand the thermal dynamics inside the unit. What is generating the heat? How does it flow or move inside the sterilizing area? How does the heat make its way to the inserted labware? How does this flow affect the placement of the application sensor? Is there a gas purge or vacuum which may affect the sensor? Are contaminants being released from the treated items which may affect the sensor?

Based on the information that you gather on the internal heat workings of the sterilizer; you can better determine the placement and type of sensor required. One location may be better than another. Several tests may be required to understand all the temperature issues. Only after you have a firm grasp of these details you can begin to look at the best way to monitor its temperature.

Sensor selection and placement

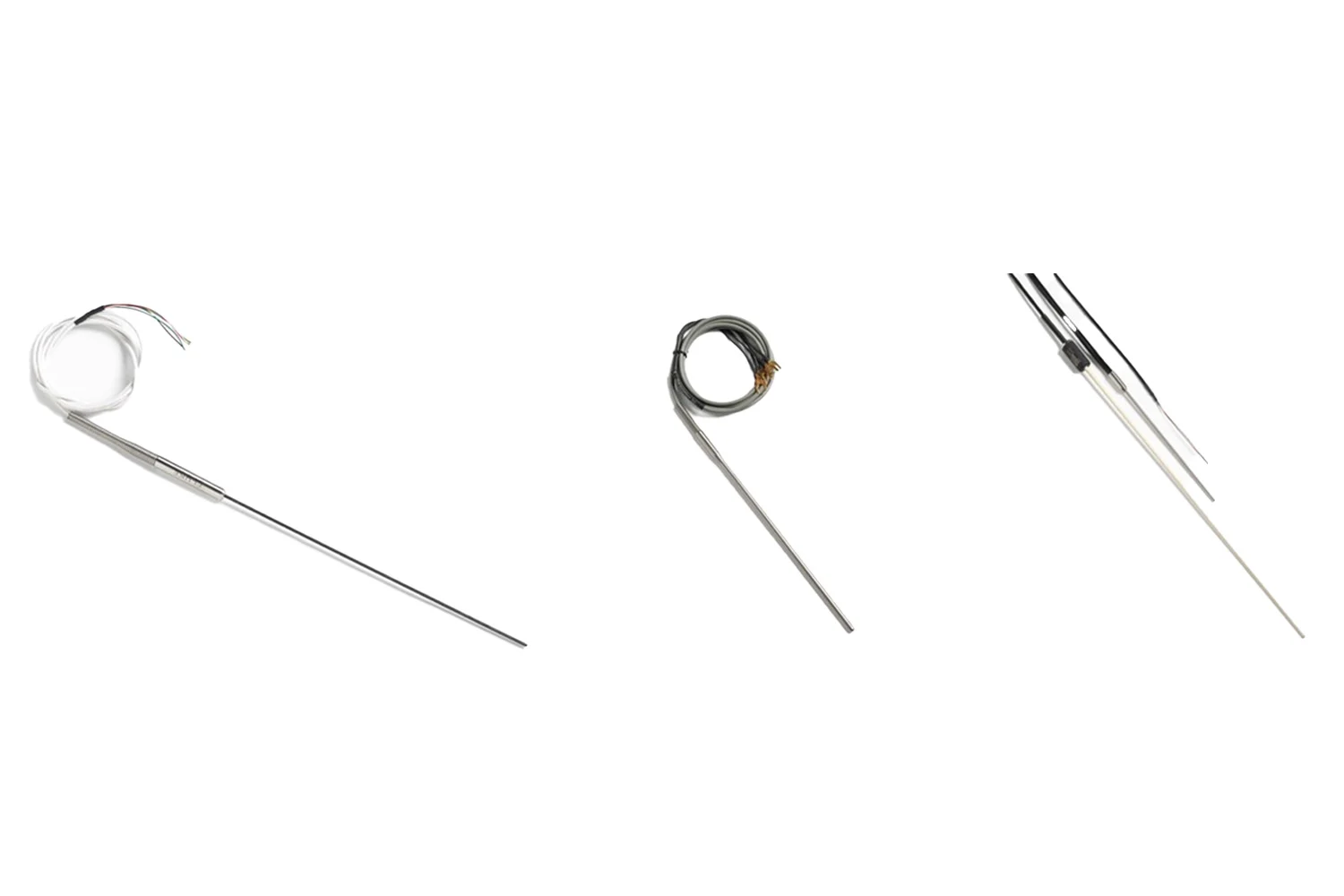

Sensor selection and placement are critical factors. The accuracy limits of the measurement depend more on the sensor selection and placement than any other single aspect. This sounds so fundamental but is often overlooked. The sensor should fit the application. Select an air probe for gas measurements and an immersion probe for liquid measurements. Consider stem effect when specifying the length and diameter. Understand how the sensor is affected by the installation and subsequent heat treating (or cold quenching for cryogenic applications). Make sure that the wire and transition junctions can withstand any extreme temperature that they may be subjected to and that they are hermetically sealed to prevent moisture ingress if necessary.

Select the type of sensor (PRT, thermistor, or thermocouple) based on the temperature range, accuracy requirements, calibration requirements, sensitivity, size, and your electronics. PRTs can be used for high accuracy requirements over a relatively wide temperature range. Thermistors can also provide high accuracy but only over a narrow temperature range. Thermocouples are often used successfully for low accuracy or for high temperature applications, or for applications where harsh environments are encountered.

As mentioned above, keep in mind how exposure to the process being measured will affect the sensor or limit its usefulness. For example, many bake-out ovens and high temperature industrial autoclaves use exposed type K thermocouples for the control sensor. We might assume that since K wire is satisfactory as a control sensor, it will be satisfactory as a monitor sensor. However, type K wire degrades very rapidly in these environments, and, if it is not protected from the product gasses or the autoclave vacuum, it will give incorrect measurements after only one use. Either a different, more suitable sensor, or a method of protection for the type K thermocouple must be used to provide good results.

Consider also how the process will stress the sensor. If the sensor just barely meets the required temperature range, the sensor will likely drift more rapidly. Drift is usually accelerated by duration at extreme temperatures. Keep in mind the length of time the sensor will be exposed to any extreme temperatures. Some types of sensors and assemblies are very susceptible to vibration. If the sensor will be exposed to vibration, make sure you choose a sensor that can handle it. Remember, the closer the application is to the limits of the sensor, the more rapidly the sensor will drift. This isn’t necessarily bad, but it must be considered.

Another, often overlooked, fundamental is the placement of the sensor. The sensing area of the sensor should be placed in the critical temperature area. Sometimes this is as simple as choosing a proper position or location in a chamber or oven. Often, this is satisfied by placing the sensor close to the test items or the items being exposed to the process. Occasionally, however, proper placement may be inconvenient, difficult, or disruptive to the process being measured. In these instances, the importance of an accurate measurement must be balanced with the difficulty of correct placement.

For example, if you want to measure the temperature of a fluid in a pipe, the sensor should be positioned inside the pipe, if possible, not attached to the outside of the pipe. Measuring the surface temperature of a pipe will not give a true indication of the temperature of the fluid. If the measurement is very important, it might be worth shutting down to process to facilitate installation. The type of sensor, placement, and desired accuracy should be considered together. Because of physical limitations, some sensor types may be better suited to certain installations. For example, thermistors are often very attractive candidates when a precise measurement is required in a very tight space. Although a thermocouple might fit, accuracy would be limited. In this example, placement and accuracy requirements point to a specific sensor type.