Differences Between Temperature and Humidity Calibration Chambers and Humidity Generators

In the realm of environmental testing and calibration, both Temperature and Humidity Calibration Chambers and Humidity Generators play pivotal roles. However, they serve distinct purposes and possess different functionalities. Understanding their differences is essential for selecting the right equipment for specific applications.

1. Definition and Purpose

Temperature and Humidity Calibration Chamber

A Temperature and Humidity Calibration Chamber is a comprehensive environmental testing device designed to precisely control and maintain specific temperature and humidity conditions. It is primarily used for calibrating, testing, and validating the performance of temperature and humidity-sensitive instruments and equipment under various controlled environmental scenarios.

Humidity Generator

A Humidity Generator is a specialized device focused solely on producing precise levels of humidity. It is typically used in applications where controlled humidity environments are required, such as in research experiments, material testing, and calibration of humidity sensors.

2. Core Functionalities

Temperature and Humidity Calibration Chamber

Dual Control: Capable of simultaneously controlling both temperature and humidity within a specified range.

Environmental Simulation: Can replicate a wide array of environmental conditions to test equipment performance under different scenarios.

Data Logging and Reporting: Often equipped with advanced data logging features to record environmental conditions over time for analysis and compliance purposes.

Automation and Precision: Features automated controls and high precision to maintain stable and accurate environmental settings.

Humidity Generator

Humidity Control: Focuses exclusively on generating and maintaining specific humidity levels.

Limited Temperature Control: May offer basic temperature regulation, but not to the extent of a full calibration chamber.

Standalone Functionality: Primarily used for generating humidity for testing or calibration purposes without the need for comprehensive environmental simulation.

Portability and Size: Generally more compact and portable compared to large calibration chambers, making them suitable for on-site or space-constrained applications.

3. Applications

Temperature and Humidity Calibration Chamber

Instrument Calibration: Calibrating temperature and humidity sensors, meters, and other environmental monitoring devices.

Product Testing: Assessing the performance and reliability of products under various environmental conditions, such as electronics, pharmaceuticals, and automotive components.

Research and Development: Providing controlled environments for experimental research requiring precise temperature and humidity settings.

Quality Assurance: Ensuring that products meet environmental standards and specifications before market release.

Humidity Generator

Sensor Calibration: Calibrating humidity sensors and hygrometers by providing a stable humidity source.

Material Testing: Testing the effects of humidity on materials, such as textiles, wood, and polymers.

Laboratory Experiments: Creating specific humidity conditions for scientific research and experiments.

Environmental Simulation: Simulating humidity conditions for niche applications where temperature control is not a primary concern.

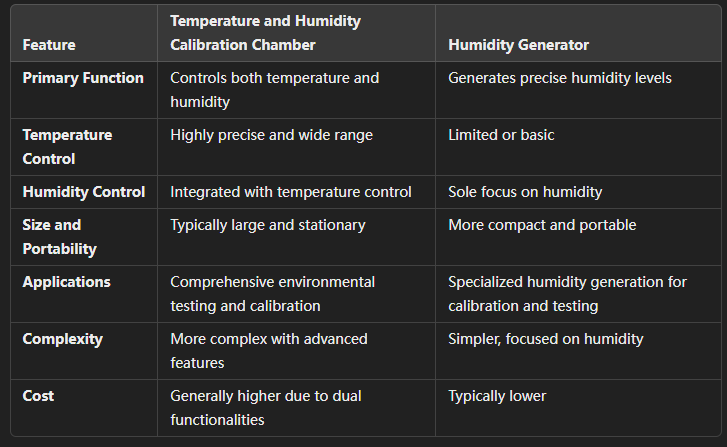

4. Key Differences

5. Choosing Between the Two

Choose a Temperature and Humidity Calibration Chamber if:

You need to control both temperature and humidity simultaneously.

Your applications require comprehensive environmental simulation.

You are calibrating instruments that are sensitive to both temperature and humidity.

You require advanced data logging and automated control features.

Choose a Humidity Generator if:

Your primary need is to generate and control humidity levels.

You have space or budget constraints that make a full calibration chamber impractical.

You are calibrating or testing equipment that only requires humidity control.

Portability is a key consideration for your applications.