Importance of Accurate Temperature Measurements

With its versatility in applications, many processes and results are affected by the results of temperature measurements. That being said, uncalibrated or faulty bimetal thermometers can have disastrous consequences. That is why understanding this instrument is crucial for businesses and organizations.

Here are examples of the critical applications of this instrument:

Medical and healthcare: Maintaining proper storage conditions for medical equipment and medications

Food and Beverage: Processing and facility conditions are important to ensure food safety and quality.

Manufacturing and Industrial Settings – The temperature of machinery, materials, and production processes is monitored.

HVAC systems: Maintain comfortable, energy-efficient climate control.

From the scenarios above, inaccurate readings can lead to outcomes that can potentially harm the health and safety of workers and customers.

Understanding Bimetal Thermometer Calibration

Keeping your bimetal thermometer accurate is a must. This can only be possible by being equipped with the proper knowledge of the proper calibration of your instrument. Professionals like Micro Precision’s technicians go through step-by-step methods in performing the calibration. Calibrating a bimetal thermometer involves several steps:

Comparison to a reference standard: The thermometer’s readings are compared to a highly accurate reference thermometer. This reference is usually calibrated and traceable to national standards.

Adjustment of the pointer: If the bimetal thermometer’s readings don’t match the reference, the pointer can be adjusted. This aligns the measurements.

Verification of accuracy: After adjusting, the thermometer’s readings are checked again. They must now match the reference standard within the specified tolerance.

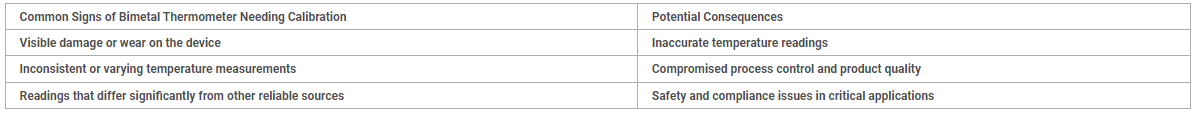

How to Know If Your Bimetal Thermometer Needs Calibration

Ensuring your bimetal thermometer’s accuracy is paramount, especially in critical fields. Regular calibration is essential for dependable temperature readings. But, how do you know when it’s time to calibrate your bimetal thermometer?

Selecting a Reliable Calibration Service Provider

Finding the right calibration service for your bimetal thermometer is crucial. Look for companies with recognized accreditations and certifications. These credentials indicate their expertise in calibration services and adherence to high standards.

Accreditations and Certifications

Top bimetal thermometer calibration providers hold recognized accreditations, such as ISO or NIST. These accreditations signify their commitment to quality standards. You can trust your thermometer will be calibrated correctly.

Also, check for bimetal thermometer calibration services with industry certifications. Look for ASME or ANSI certifications. These certifications highlight their expertise in temperature measurement and calibration.

Choosing a bimetal thermometer calibration provider with the right qualifications is key. It ensures your temperature-sensitive equipment is accurately calibrated. This maintains the integrity of your critical applications and processes.

Proper Handling and Storage of Bimetal Thermometers

Follow proper handling and storage tips to keep your bimetal thermometer accurate and long-lasting. These steps ensure your device provides reliable temperature readings for many years.

When using a bimetal thermometer, avoid physical shocks or impacts. Such incidents can misalign internal parts, resulting in incorrect readings. Always hold the thermometer by its case, and avoid twisting or bending the stem.

Storing your bimetal thermometer correctly is also vital. It should be kept in a cool, dry spot, away from sunlight and extreme temperatures. High heat or humidity can warp the bimetal coil, impacting its accuracy.

Store the bimetal thermometer in a protective case or holder when not in use.

Avoid leaving the thermometer in environments with rapid or significant temperature fluctuations.

Periodically inspect the thermometer for any signs of damage, such as cracks, dents, or corrosion.

Recordkeeping and Documentation

Accurate records of your bimetal thermometer’s calibration history are crucial. They ensure compliance with industry standards and maintain the precision of temperature readings. Your documentation should outline the calibration process, the technician involved, and the results.

Proper recordkeeping offers several advantages:

It demonstrates your commitment to quality and safety standards.

It helps identify trends or patterns in your thermometer’s performance.

It facilitates troubleshooting and diagnostics when issues arise.

It ensures traceability and accountability during audits or inspections.

The documentation should include:

The calibration date.

The technician’s name and qualifications.

The calibration method used.

Pre- and post-calibration readings.

Any adjustments or repairs to the thermometer.

A calibration certificate or report.

By meticulously recording and storing this data, you demonstrate your dedication to bimetal thermometer calibration recordkeeping and documentation. This ensures the reliability and precision of your temperature measurements for the long term.

Keeping your bimetal thermometer accurate is a big factor in reliable temperature readings and meeting industry standards. Knowing when your device needs bimetal thermometer calibration is key. Following recommended calibration intervals and choosing a trusted service provider ensures your temperature measurements are precise for years.

Calibration unlocks your bimetal thermometer’s full potential and protects your critical applications. Regularly checking your device’s performance and fixing issues quickly prevents inaccurate readings. This keeps you in line with important regulations.

Regular bimetal thermometer calibration is more than a best practice; it’s essential for your equipment’s reliability and longevity. By focusing on this critical maintenance, your bimetal thermometer will remain a reliable tool in your operations.