Pressure Switch Calibration

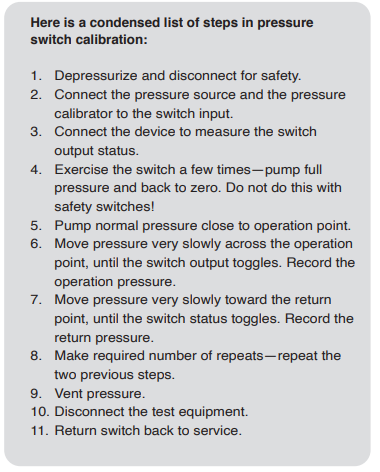

Pressure switches are very common instruments in the process industry, and various kinds of pressure switches are available. Like many instruments, pressure switches need to be calibrated to ensure their accuracy and reliability. Switches are a bit more difficult to calibrate than transmitters. The wrong kind of calibration can cause many errors in the calibration result. In this article, we will look at how to properly calibrate pressure switches. Before rushing into the calibration process, let’s discuss some fundamental characteristics and terminology of pressure switches.

How does a pressure switch work?

Briefly stated, a pressure switch is an instrument that measures pressure and that has an electrical switch function programmed to operate at a certain pressure. For example, the pressure switch can be set so that when no pressure is connected (open to atmosphere) the switch is closed, but when pressure exceeds 10 psi, the switch opens. Again, when the pressure drops below 10 psi, the switch closes.

Pressure switch terminology

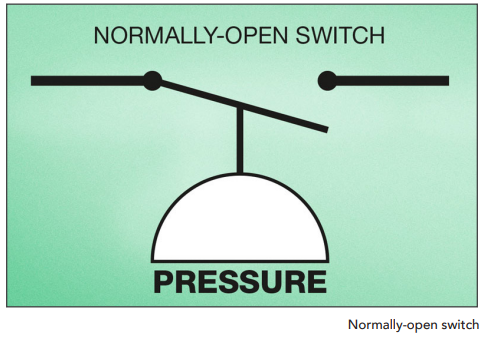

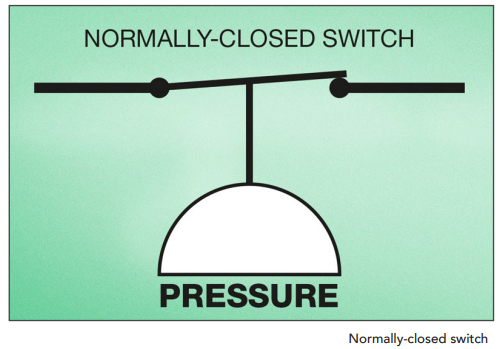

Let’s very briefly discuss the related terminology: Normally open/Normally closed Some switches have the switch terminals open when no pressure is connected, called normally open (NO) or a closing switch. The opposite is a normally closed (NC) or opening switch. The selection depends on the kind of circuit you want to drive with the switch.

What is “normally”? There is some debate about the definition of the normally open/closed switch. Most commonly, it is defined as the state of the pressure switch output when it is not connected to any pressure, i.e., it has no physical stimulation. Some may define the “normal” state as the state of the switch during the normal operation of the process (untripped). A normally open switch is open when no pressure is connected. When enough pressure is applied, the switch closes.

A normally closed switch is closed when no pressure is connected. When enough pressure is applied, the switch opens.

A switch always has some deadband, which is the difference between the two operating points (opening and closing points). Deadband is required, because if a switch opens and closes at the same point, it could start oscillating when the pressure is on that limit. Also, if there was no deadband, the switch could control the circuit on and off with a high frequency. For example, a closing (NO) pressure switch may close at 10 psi pressure and open again at 9.5 psi pressure, so there is a 0.5 psi deadband. Some switches operate at rising pressure, others with falling pressure. Sure, you always get one of the functions with rising and the other with falling, but the primary desired function happens in one direction. There are pressure switches that operate with different pressure types: gauge, absolute, differential, or vacuum pressure. Some older switches are mechanical (or even pneumatic), so inside the switch the pressure causes the switch to change its state. Most newer types are electronic or digital, so they measure the pressure and control the switch output accordingly. Many modern switches are programmable, so it is easy to set the desired operating points. While mechanical switches do not need a power supply, the electrical ones do. When selecting the switch type, consider the state, so that if the power supply fails or a cable becomes loose, the switch status remains safe. And in the case of a safety switch, configure it so that if a cable comes loose, the alarm goes on. For example, if it is normally open (closing switch), you will not notice anything if the cable comes loose. The switch is still open, but it will not make the desired action when the switch closes. So all in all, you should design it to be fail safe. There are also dry and wet switches. A dry switch has the connections open or closed, so it works like a mechanical switch. A wet switch has two different voltage values representing the two output states. The output of an electrical wet switch can be a voltage signal with two levels, a current signal, or an open collector type signal. Sometimes the switch function can also be done in the control system, by measuring the current signal from a transmitter and programming the switch-like function to control something based on the signal level. In practice, industrial switches often have double switch contacts that can be programmed separately. This can be the normal “Lo” and “Hi” points, but also “Lo Lo” and “Hi Hi” points. Although the Lo and Hi are the normal control points, the Lo Lo and Hi Hi are alarm limits that will control for more serious alarm activities.

Safety pressure switches

Safety switches are switches used in safety instrumented systems. These switches have certain safety classifications, and the calibration of the switches is regulated. A big difference with these switches is that they stay static most of the time without ever functioning. So, they do not toggle open and closed in normal usage. They just wait until the safety alarm level is met, and then they operate.

Because these switches rarely operate, there is a risk that they will get stuck and not work when they should. When calibrating, do not exercise these safety switches prior to calibration; instead, capture the very first point when the switch operates. Sometimes the first operation requires more pressure than the operations after a few exercises. Normal switches are typically exercised a few times before calibration, but that should not be done for the safety switches. In a safety switch, the operation point is critical, but often the return point is not relevant and may not require calibration.

How to calibrate pressure switches

Now, let’s discuss how to calibrate pressure switches.

Preparations and safety

If the switch is installed in the process, it is very important to make sure it is isolated from the pressure line. You also need to make sure to disconnect any circuit that the switch is controlling— you do not want to generate a safety alarm or for big valves to start opening/closing or pumps to start operating. Some switches may have mains voltage, or another dangerous voltage, across the switch terminals when they open, so make sure that it is isolated.

Pressure ramp

To calibrate a pressure switch, you need to provide a slowly changing pressure ramp, moving across the operating points of the switch. Depending on the switch type, you need to first supply a suitable pressure to start the calibration. Often you can start from atmospheric pressure, but in some cases, you need to pump a high pressure and start slowly decreasing the pressure toward the operation point. Or you may need to provide a vacuum to start from. This depends on the switch to be calibrated. There are different ways to provide the input pressure. You can use a calibration hand pump with a fine adjustment control; you can use shop air supply with a precise pressure controller; or you can use an automatic pressure controller. It is vital to provide a slow pressure ramp, so that you can see the precise pressure whereby the switch operated. If the pressure changes too quickly, you cannot accurately capture the pressure point when the switch operated. However, some tools (like the Beamex MC6) can automatically capture the exact pressure during the very moment when the switch changed its status. Anyhow, remember to change the pressure very slowly when you are approaching the operation points of the switch! You may change the pressure faster when you are not yet close to the operation points.

Measuring the switch output

You need a tool to measure the switch terminals. If it is a dry switch, with an open and close output, you may use an ohm meter. If the output is electrical, you will need to find a tool that can measure the output. In some cases, it may be a voltage meter, or a current meter. For electrical outputs, it is sometimes a bit difficult to find how to measure the output. You should be able to recognize the two states of the output and to see when the state changes. With some tools, you can program a trigger level that suits the switch in question, which enables the status change to be captured automatically. This is how the Beamex MC6 works.

Capturing the operation points

In the switch calibration, you need to capture the input pressure at the very moment when the output state changes. You can try to capture the input pressure manually. For example, when the switch state changes, you stop the ramp and check the input pressure (on the device/calibrator that is measuring the input pressure). Most likely there is some delay in your reflexes, so the pressure is already different from what it was during the switch operation moment. That is the main reason you should provide a very slow input pressure, so it does not change that much during the delay of your reflexes.

Some devices can capture the input pressure automatically at the very same moment when the switch output changes its state. These devices can interpolate between the pressure measurement readings. Let me explain: a digital pressure measurement device measures the pressure a few times every second. It may happen that the switch operates in between the two consecutive pressure measurement readings. In that case, the calibrator looks at the time stamp of the switch operation and interpolates between the two consecutive pressure measurement results to get the exact pressure value during the switch operation moment.

Delayed output

Some industrial switches have a delay added to the output so that it does not work too quickly. You should find out if your switch has delay. If it does, the calibration needs to be done even slower than normally.

With some added delay, by the time the output toggles, the input pressure is already far away from the point that actually triggered the output to toggle.

Naturally, you need to document the switch calibration results. Also, you need to calculate the errors found in the calibration and compare them to the max allowed tolerance for that switch to see if it passed or failed calibration. If the switch fails the calibration, then you need to either adjust the switch or replace it. Even if it passes the calibration, you should still analyze how big the error was. If the error was close to the tolerance limit, or if it had drifted much since the last calibration, it is good to adjust it to avoid a fail result in the next calibration. And as with every calibration, based on the calibration result history, you should consider if the calibration period should be changed. You do not want to waste resources on calibrating too often, but you also do not want to calibrate so seldom that you get a failed calibration result. A failed calibration result should anyhow always start an investigation of the consequences. This can be expensive and work intensive.

Documentation, metrological traceability, calibration uncertainty

As documentation is included in the formal definition of calibration, it is a vital part of every calibration. This is also valid for pressure switch calibration, typically in the form of a calibration certificate. The calibration equipment used should have a valid metrological traceability to the relevant standards, otherwise the calibration does not ensure traceability in the switch calibration. The calibration uncertainty is a vital part in every calibration. If the calibration equipment (and calibration method and process used) is not accurate enough for the pressure switch calibration, then the calibration does not make much sense. What is the point in using a 2 percent accurate calibrator to calibrate a 1 percent accurate instrument?